-

Auto Steering Systems

Traditionally, mixed fleets created chaotic cabs with separate monitors for every implement, causing operator fatigue and inefficiency. So, what is ISOBUS? It is the industry-standard solution to this connectivity crisis.

By streamlining communication between tractors and implements into a single "plug-and-play" network, ISOBUS eliminates clutter and serves as the backbone of modern precision farming.

At its core, ISOBUS (technically known as ISO 11783) is a standardized communication protocol designed for agricultural and forestry machinery. Before its adoption, manufacturers utilized proprietary systems that could not communicate with one another. For instance, a John Deere tractor often could not effectively control a Kuhn sprayer without installing a separate harness and display.

ISOBUS solves this by utilizing the Controller Area Network (CAN) bus system—derived from the SAE J1939 standard—to create a universal language. This allows a single terminal in the tractor cab to control implements from different manufacturers, provided they are ISO-compliant.

While ISO 11783 provided the technical framework, the AEF ISOBUS (Agricultural Industry Electronics Foundation) provided the necessary governance. Established in 2008, the AEF serves as the global certification body ensuring practical compatibility.

The AEF clarifies ambiguities in the original standard to prevent compatibility issues. Their critical roles include:

l Standardization: Coordinating technical improvements to ensure the standard evolves alongside modern technology.

l Certification: Managing the Conformance Test Tool. Only equipment passing this rigorous testing receives the "AEF Certified" label.

l Database Management: Maintaining a comprehensive database for dealers and farmers. This allows users to verify which functionalities (like Section Control) are supported by specific tractor and implement combinations.

EFIX eSteer 10 features AEF-certified ISOBUS UT, AUX-N, TC-BAS, TC-GEO, and TC-SC functions

To understand how ISOBUS works, we must examine the physical and digital architecture connecting the machinery.

Also known as the Virtual Terminal (VT), the UT is the operator's primary interface (HMI). It replaces the stack of multiple monitors in the cab. When an ISOBUS implement is connected, it uploads its specific graphical interface to the UT. This allows the operator to control various implements, such as balers or sprayers, from the same screen used for tractor guidance.

The TECU acts as a gateway connecting the tractor’s internal proprietary CAN bus to the ISOBUS network. It translates and shares standardized tractor data—including ground speed, PTO rpm, and linkage position—allowing the implement to react to the tractor's actual performance.

The IECU is the "brain" located on the implement. It monitors sensors (e.g., seed flow, nozzle pressure) and controls actuators (e.g., hydraulic motors, valves). It also stores the user interface required by the Universal Terminal.

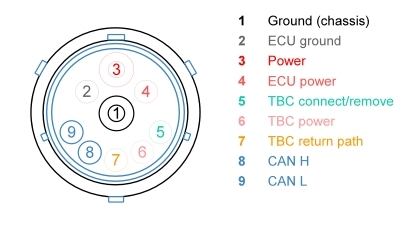

The physical connection follows ISO 11783-2 standards. One of the key components is the ISOBUS Breakaway Connector (IBBC). Built to operate reliably in harsh conditions including dust, moisture, and vibration, the IBBC offers standardized electrical connectivity and communication channels. The standard defines an "Active" socket (power termination, usually on the tractor) and a "Passive" socket (on the implement).

Picture shown: Implement Bus Breakaway Connector

Source: https://www.csselectronics.com/pages/isobus-introduction-tutorial-iso-11783

True interoperability relies on "Functionalities"—software modules defined by the AEF that dictate how ISOBUS works in the field.

The Task Controller bridges the field machine and the farm office, managing precision farming tasks. It is divided into three parts:

l TC-BAS (Task Controller Basic): Handles the documentation of total values. It records data including total area worked, time, and input volume. This data is exported in ISO-XML format for farm management software.

l TC-SC (Task Controller Section Control): A key feature for cost reduction. TC-SC uses GPS position to automatically switch implement sections (like boom nozzles or planter rows) on and off. This prevents overlap in headlands, directly saving inputs.

l TC-GEO (Task Controller GEO-based): Enables location-based automation. It allows the system to read prescription maps (e.g., variable rate seeding) and automatically adjusts the implement's application rate based on GPS coordinates.

While touchscreens are versatile, physical buttons often suit repetitive tasks better. AUX allows operators to assign implement functions to external joysticks or the tractor’s multifunction lever.

l AUX-O (Old): The legacy standard, currently being phased out.

l AUX-N (New): The current standard offering greater flexibility, though generally incompatible with AUX-O.

TIM represents advanced automation. Unlike standard setups where the tractor controls the implement, TIM allows the implement to control the tractor. For example, a baler can command the tractor to stop, eject the bale, and resume movement. This bidirectional communication optimizes cycle times and reduces operator error.

LOG is a standardized method for recording independent device values, such as yield data or fuel consumption, regardless of the active task. This ensures compatibility with telemetry systems and FMIS.

Adopting this technology requires balancing initial complexity with long-term efficiency.

l Complexity: The ISO 11783 standard is dense. Early implementations suffered from varying interpretations by manufacturers. While AEF has largely resolved this, troubleshooting communication errors between different equipment generations can still require technical expertise.

l Compatibility Nuances: "ISOBUS Ready" does not guarantee every feature. A terminal might support the UT but lack the Task Controller (TC-SC) unlock needed for section control. Farmers must verify specific functionalities via the AEF database to ensure the hardware meets their needs.

l Input Savings and Economic Efficiency: Economic efficiency is a primary driver for adoption. Utilizing TC-SC (Section Control) and TC-GEO (Variable Rate) reduces material waste by minimizing overlap. Studies indicate overlap reductions of over 15%, significantly lowering fertilizer and chemical costs.

l Streamlined Data Management: ISOBUS automates documentation. Instead of manual recording, TC-BAS digitally logs what was applied, where, and when. This data flows into farm management software, facilitating data-driven decisions and traceability for food supply chains.

l Improved Operator Ergonomics: Consolidating controls onto a single screen creates a safer, organized cab. Reducing the cognitive load—eliminating the need to scan multiple monitors—combined with TIM automation, significantly lowers operator fatigue, leading to fewer accidents during peak seasons.

To fully leverage ISOBUS implements, a guidance system should act as the central hub of operations. The EFIX eSteer 20 Max auto steering system excels in this role.

Key Specifications and Features:

l Full ISOBUS Capability: The 12.1-inch display acts as a powerful central hub, fully supporting UT, TC-SC, and TC-GEO to control implements and manage prescription maps from a single terminal.

l Exceptional Versatility: Maintains ±2.5 cm accuracy across speeds from 0.1 to 30 km/h, handling tasks from ditching to spraying. It also features flexible auto U-turn modes for efficient navigation in irregular fields.

l Advanced Connectivity: Supports diverse GNSS modes, including PointSky for high accuracy without base stations, alongside extended options for visual and row guidance.

By pairing a robust guidance solution like the eSteer 20 Max with ISOBUS implements, farm owners bridge the gap between mechanical execution and digital agronomy.

ISOBUS has evolved from a technical protocol into the backbone of efficient farming. It empowers farmers to select the best equipment regardless of brand, ensuring machines work in harmony. From the basic utility of the Universal Terminal to the advanced automation of TIM, ISOBUS offers a clear path toward lower costs and higher yields.

For operators modernizing their fleet, combining AEF-certified implements with a high-performance control hub like the EFIX eSteer 20 Max unlocks the full potential of precision agriculture!

Relevant information:

1. https://www.csselectronics.com/pages/isobus-introduction-tutorial-iso-11783

2. https://www.aef-online.org/fileadmin/user_upload/Content/pdfs/AEF_handfan_EN.pdf

09 Jan 2026

09 Jan 2026

09 Jan 2026

01 Aug 2025